turbo air technology

Self-cleaning condenser

-

Patented Standard Feature

Turbo Air’s Self-cleaning Condenser is a standard feature. Our customers can benefit from this excellent option on most of our product lines without spending any extra money.

Turbo Air’s top priority is our customers. We understand your business. Turbo Air will continue to strive to provide better solutions to this industry and, most importantly, to our customers.

-

Dirty Condenser

Busy marketplaces and restaurant kitchen spaces with heavy traffic accumulate massive amounts of dust quickly, leading to a dirty condenser. Dirty condensers can cause major issues when neglected without proper maintenance such as; increased energy consumption, compressor failure, health inspection failure and manufacturer warranty void.

Dirty condenser coils are one of the most frequent service problems in commercial refrigeration.

-

How Does it work?

Turbo Air’s patented Self-cleaning Condenser is an innovative feature that uses a fine mesh filter to catch the dust, while the rotating brush moves up and down 2~3 times a day to remove the excess outward and away from the condenser, effectively preventing dust from accumulating in the first place. This allows your system to maintain the highest efficiency while mitigating premature system failure.

eco-friendly turbo air

Natural Refrigerant

Natural refrigerant is used in all Turbo Air refrigerators.

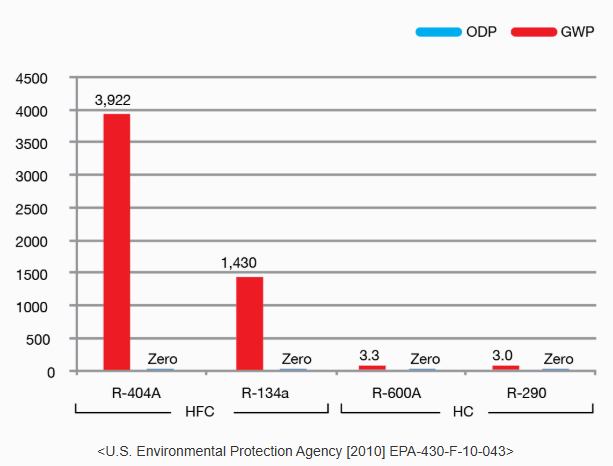

The most common refrigerants that have been used in the industry are HFCs (hydrofluorocarbons R-134a, R-404A), replacements for CFCs (chlorofluorocarbons) which are harmful substances proven to deplete the ozone layer. HFC’s are not directly ozone-depleting but these strong greenhouse gases have been shown to have a negative impact on the environment, contributing to global warming up to 4,000 times more than CO2. These GWP refrigerants are listed among substances regulated by the Kyoto Protocol of 1992, and HFC substances such as R-134a and R-404A will be banned by new U.S government regulations starting January 1, 2019.

The industry must embrace the new climate-friendly natural refrigerant HC (hydrocarbons).

what is hydrocarbon?

HC (hydrocarbon) is a sustainable alternative to HFC. Hydrocarbons (R-600A, R-290) are natural refrigerants that have no ODP (ozone depleting potential) and very low GWP (global warming potential). Moreover, HC based equipment have been shown to be more energy efficient compared to HFC based equipment, which translates to lower operating costs. The EPA approved R-290 (Propane) and R-600A (Isobutane) as acceptable refrigerants for use in commercial refrigeration, stand-alone equipment refrigerators, and freezers.

Turbo Air is committed to the environment with innovative and eco-friendly technology!

By utilizing our innovative, eco-friendly technology, Turbo Air has now replaced all previous refrigerants with climate-friendly hydrocarbons R-600A (Isobutane) and R-290 (Propane). In our efforts to protect our environment, we have decreased energy consumption by 25%.